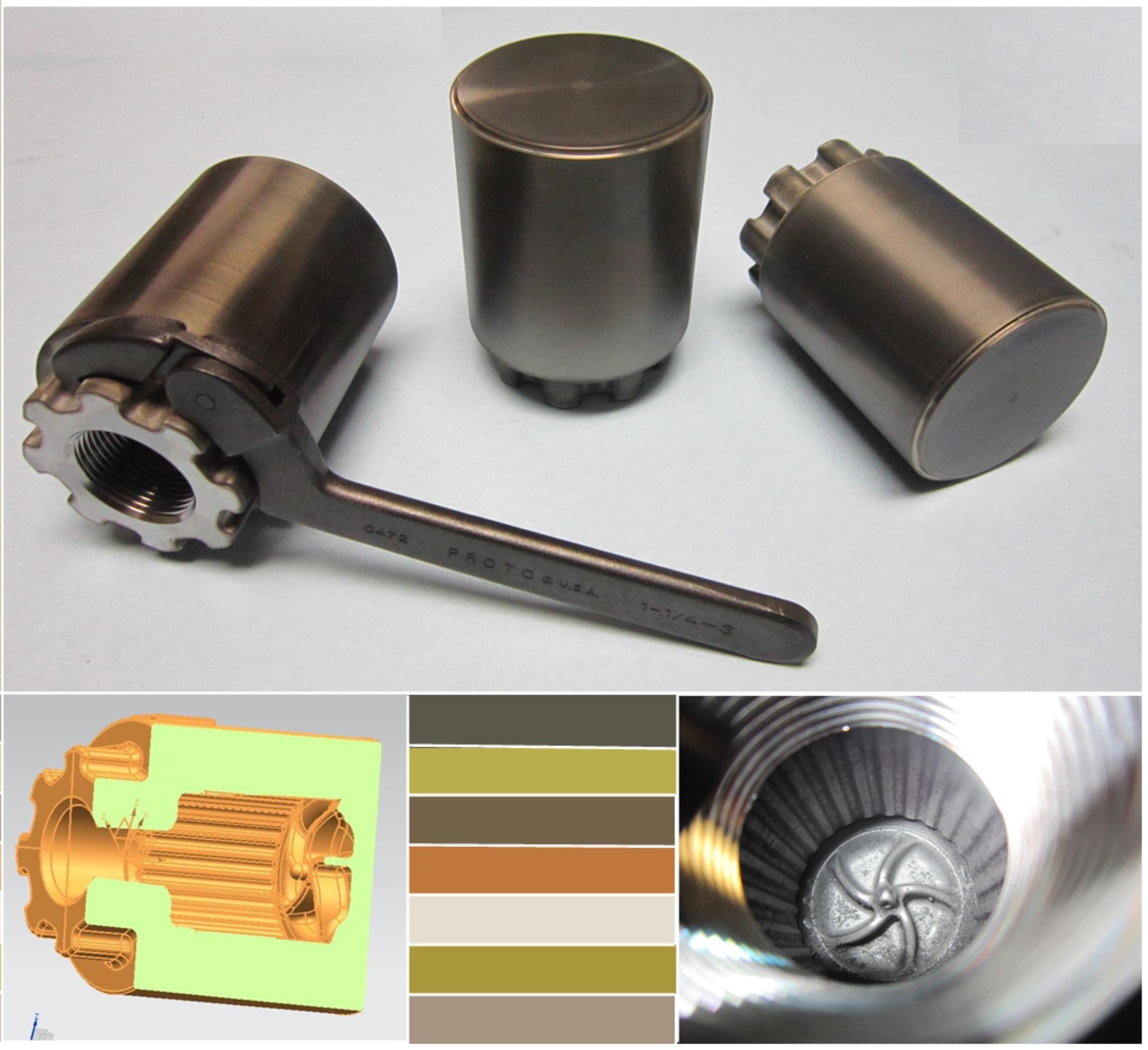

Cold Chamber Shot End Components

Diversified Tooling Innovations produces all types of expendable shot end components used in the die cast industry such as Shot Sleeves, Plunger Rods and Plunger Tips. DTI also provides their customers with a Shot Sleeve Reconditioning program. By repairing and modifying customer's existing shot sleeves and plunger rods we offer them cost savings over purchasing new product.

Your Single Source for New and Reconditioned

DIE CAST TOOLING

Discover our Quality, Reliability and Personal Service

Shot Sleeves

Plunger Rods

Plunger Tips

Manufactured and Heat Treated to Your Specifications

CALL

262-598-9989

NEW

Steel Plunger Tip

with

Internal Cooling Structure

In a machined product, like a cold chamber shot sleeve, reliability is determined

by the steel quality, the heat treatment and the nitride process. At Diversified

Tooling Innovations, cold chamber shot sleeve heat treatment consists of

austinitizing with triple temper. The third temper improves size stability

and ductility, which reduces cold chamber shot sleeve cracking and breakage.

Nitriding is a 48-72 hour cycle process, which guarantees we achieve your

engineered case depth. Cold chamber shot sleeve heat treatment and nitriding

are processes monitored by trained metallurgists. All equipment is calibrated

and maintained by experts. With DTI you are assured our cold chamber shot

sleeves will give longer life, less down time and more shots.

In a machined product, like a cold chamber shot sleeve, reliability is determined

by the steel quality, the heat treatment and the nitride process. At Diversified

Tooling Innovations, cold chamber shot sleeve heat treatment consists of

austinitizing with triple temper. The third temper improves size stability

and ductility, which reduces cold chamber shot sleeve cracking and breakage.

Nitriding is a 48-72 hour cycle process, which guarantees we achieve your

engineered case depth. Cold chamber shot sleeve heat treatment and nitriding

are processes monitored by trained metallurgists. All equipment is calibrated

and maintained by experts. With DTI you are assured our cold chamber shot

sleeves will give longer life, less down time and more shots.